THE PREPARATION AND RESEARCH OF THE

SURFACTANT FOR

IRON NITRIDE MAGNETIC

FLUID

Xuehu L., Rui Q.,

Zhongfan L., Xiuling Zh., Hong A.

Laboratory of

plasma, Physics Department, Dalian University, Dalian, China.

The surfactant for iron nitride magnetic fluid-imido-polyamin was prepared using the organic synthesis method, and its properties were tested. The result shows that the main influencing factor to the structure of the surfactant is the mole ratio and the temperature of the reaction between polyethylene polyamine and fatty acid. Also the stability of the surfactant and magnetic saturation’s intensity for the nitride iron magnetic fluid are detected. The surfactant that prepared with this optimized technological process has a satisfactory catalytic activity.

The special function of the surfactant lies in that it can meet both the character of a certain carrying liquid and the requirement from the interface of the magnetic particles. The surfactants a steady colloidal solution which coated the magnetic particles, should have such a property; one end should produce the permanent pinprick effect to the magnetic particle interface (chemical adsorption); another end should be extremely easy to disperse in a certain carrying liquid (dissolve in the carrying liquid). This can prevent the particles from deposition caused by the Van der Waals force, magnetic force and gravity, and make them disperse in the liquid. At present, the surfactant for preparing iron nitride magnetic fluid is Poly Buteny Sunccini Imide,called PBSI for start. The special function of the surfactant lies in that it can meet both the character of a certain carrying liquid and the requirement from the interface of the magnetic particles. The surfactant a steady colloidal solution which coated the magnetic particles, should have such a property: end should produce the permanent pinprick effect to the magnetic particles interface (chemical adsorption); another and should be extremely easy to disperse in a certain carrying liquid (dissolve in the carrying liquid). This can prevent the particles from deposition caused by the Van der Waals force, magnetic force and gravity, and make them disperse in the liquid. At present, the surfactant for preparing iron nitride magnetic fluid is Poly Buteny Sunccini Imide, called PBSI for short. It is made by Japanese LUBRIZOL Company. Originally Lubrizol-941 is belong to one kind at lubricting oil additive, instead of a surfactant for iron nitride magnetic fluid. But the iron nitride magnetic fluid made by it has a higher saturation intensity and better stability. The surfactant a made by Japan. Therefore, it is not convenient to purchase and is expensive. To meet the need, we develop a new kind of surfactant, specially used in the producing of iron nitride magnetic field. Referring to the structure of PBSI, prepare the surfactant of amine group. It is prepared by its dehydration of polyethylene polyamine and fatty acid under a certain temperature. The malt reaction equation is as followings:

A: RCOOH + H2NR1NH2

® RCONHR1NH2

B: 2RCOOH + H2NR1NH2 ® RCONHR1NHCOR

(1) Draw polyethylene polyamine and carboxylic acid in a certain ratio, add them into a round bottom flask. (2) Weigh certain amount of solvent, infuse from the mouth of the condensation pipe (3) Heating and write down the temperature of mixture distillation point consist of water and solvent (4) Heating for 8 – 10 hours continuously until the water in the lower floor of the water dividing didn’t increase any more. (5) Take off water-dividing, load the apparatus according to (figure 1). Keep temperature above 120°C. Smoke solvents for an hour with vacuum pump. The experimental device shows as Figure 1:

Although the trial-produced surfactant has nine kinds of ways of producing the iron nitride-magnetite fluid by plasma method, we need to make further comparisons and judgments.

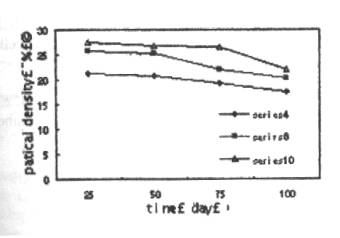

Demonstrate the stability of the iron nitride magnetic fluid by the particle density-changing curve. Showed as Figure 2: the stability of series 4 and 8 are closed to that of Japanese PBSI.

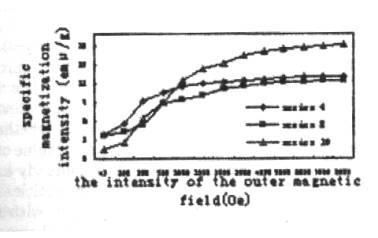

As Figure 3 showed, under the same magnetic field, the specific magnetization intensity of the iron nitride magnetic fluid made by the series 3 and series 8 surfactant is corresponding to that of the Japanese PBSI.

By adopting the solvent method, polyethylene polyamine reacted with unsaturated fatty acid to produce the surfactant, then using the surfactant to prepare the iron nitride magnetic fluid (the satisfactory ratio is 1 / 4). The stability the surfactant is comparable to that of imported from Japan. It provides a basis of the special surfactants for the Chinese domestic production of the iron nitride magnetic fluid.

Figure 1

Figure 2

Figure 3