Magnetic alginate microparticles for purification of a-amylases

M. Safafikovaa, I. Royb, M.N.

Guptab, I. Safafikc

1 Laboratory of

Biochemistry and Microbiology, Institute of Landscape Ecology, Na Sadkach 7, 3

70 05 Ceske Budejovice, Czech Republic

b Chemistry

Department, Indian Institute of Technology, Delhi, Hauz Khas, New Delhi 110016,

India

c Department of

General Biology, University of South Bohemia, Branisovska 31, 370 05 Ceske

Budejovice, Czech Republic

Abstract

Spherical magnetic alginate microparticles (25-60 fim

in diameter) were prepared using the microemulsion system, with water-saturated

1-pentanol as the organic phase. The limited solubility of 1-pentanol in water

enabled simple removal of the organic solvent from the prepared beads with water

solution. The prepared alginate microparticles were used as magnetic affinity

adsorbents for specific purification of a-amylases. Enzyme activity was eluted by 1.0 M

maltose. a-Amylases from Bacillus

amy-loliquefaciens and porcine pancreatic acetone powder were purified 9- and

12-fold with 88 and 96% activity recovery, respectively.

Keywords: Alginate;

Ferrofluid; Magnetic fluid; Magnetic microparticles; Magnetic nanoparticles;

Amylases

1. Introduction

Alginates (polysaccharides consisting of man-nuronic and guluronic acids) are naturally occurring biopolymers and have many applications in various areas of biosciences and biotechnology (e.g. as a matrix for the entrapment and/or delivery of a variety of proteins and cells), and in the food and beverage industry (as a thickening or a gelling agent and a colloidal stabilizer; Smidsrod and Skjåk-Bræk, 1990).

Alginates offer a relatively inert aqueous environment

within the matrix and high gel porosity allows high diffusion rates of

macromolecules. Alginates also show unexpected affinity towards a-amylases (Roy et al., 2000).

For biotechnology applications, alginate is mainly used in the bead form

usually prepared by a syringe with a needle; the diameter and shape of the

beads formed is dependent on the size of the needle and the viscosity of the

alginate solution (Smidsrod and Skjåk-Bræk, 1990).

Several well known methods (atomization, spraying and

water-in-oil emulsifica-tion methods) can also be used to prepare alginate

microbeads that are less than 0.2 mm in diameter (Gombotz and Wee, 1998).

Alginate beads with incorporated

ferromagnetic materials represent very promising materials for various

applications. Magnetically modified beads easily manipulated with an external

magnetic field can be used when working with difficult to handle samples, such

as biological crude broths, which are often viscous suspensions (Safarik and

Safarikova, 1997; Safarikova and Safarik, 2001). Magnetic alginate beads have

been already used for affinity separation of various starch-degrading enzymes

such as a-amylase, (3-amylase, glucoamylase and

pullulanase (Teotia and Gupta, 2001, 2002). Other applications involve immobilization

of yeast cells (Brady et al., 1996) and immobilization of affinity ligands

(Burns et al., 1985). The goal of our work was to develop a simple procedure

for rapid preparation of magnetic alginate microparticles using microemulsion

procedure in a water-in-oil emulsion system. The microemulsion was formed using

water-saturated 1-pentanol as the oil phase. It is further shown that these

microparticles also constitute effective affinity materials for a-amylases. The

efficiency of the alginate microparticles was compared with alginate

macroparticles described in an earlier work (Teotia and Gupta, 2001). Alginate

microparticles were also used for the isolation of porcine pancreatic

a-amylase from porcine pancreatic acetone powder containing a number of

contaminating hydrolases. Thus, the selectivity of the alginate as a

macroaffinity ligand was established.

2. Materials and methods

2.1. Materials

Sodium alginate was from BDH Laboratory Supplies,

United Kingdom. 1-Pentanol was from Aldrich, USA while sodium dodecylsulphate

(SDS) was from Serva, Germany. Citrate-based magnetic fluid was prepared as

described recently (Domingo et al., 2001); the concentration of magnetite was

37 mg/ml (determined using a spectrophotometric procedure; Kiwada et al.,

1986). Porcine pancreatic acetone powder (sold as pancreatin) was purchased

from Sisco Research Laboratories, Mumbai, India. BAN 240 L (commercial

preparation of a-amylase from Bacillus amyloliquefa-ciens) was a product of

Novo Nordisk A/S, Denmark and was obtained from Arun & Co., Mumbai, India.

All other chemicals used were of analytical grade.

2.2. Preparation of magnetic alginate microparticles

Two milliliters of 2% sodium alginate solution was

added to 60 mg of SDS in a test tube. After thorough mixing and SDS

dissolution, 600 fxl of citrate stabilized ferrofluid was added and the content

was mixed well again. Eight milliliters of water-saturated 1-pentanol was then

added and the whole content

was vortexed using a vortex mixer (IKA minishaker,

Model MS1, obtained from Fisher Scientific, Czech Republic) at the maximum

speed for ca. 5 min. Then the content of the test tube was rapidly poured to

another vortexed test tube containing 10 ml of 5% calcium chloride solution and

vortexing continued for another 2 min. Then the bead suspension was allowed to

stand for 15 min, the beads were separated using an appropriate magnetic

separator and washed repeatedly with 5% calcium chloride solution until the

1-pentanol was washed out. Finally, the suspension was filtered through a sieve

(mesh size: 100 mm). The beads were stored in 5%

calcium chloride solution at 4 °C. The size of magnetic alginate microparticles

was measured using optical microscopy.

2.3. Estimation of enzyme activities and amount of

protein

Activity of a-amylases was estimated using starch as

the substrate (Dekker, 1977). In the case of porcine pancreatic amylase, the

assay was carried out at pH 6.9 (Dekker, 1977), whereas in the case of the

bacterial enzyme, the assay was done at pH 5.6 [Product sheet on BAN, NOVO

Nordisk A/S (1990)]. Bradford assay was used for the protein determination with

bovine serum albumin as a standard (Bradford, 1976).

2.4. Binding capacity of magnetic alginate

microparticles for a-amylases

Binding capacities of the microparticles were measured

by equilibrating 1 ml of different concentrations of the enzyme (bacterial

enzyme, 0.5-1 ml; porcine pancreatic enzyme, 0.4-1 ml, appropriately diluted in

the respective assay buffers up to a total volume of 1 ml) with 1 ml of the

magnetic alginate microparticles (settled volume, after decanting the excess

buffer) overnight at 25 °C. After equilibration, aliquots were removed and the

amylase activity in the supernatant was measured to calculate bound amylase

activity per ml of the alginate microparticles.

2.5. Purification of a-amylases

The magnetic alginate microparticles (16 ml, settled

volume) were equilibrated with 20 ml each of porcine pancreatic and bacterial

a-amylase preparations at

25 °C for 1 h. After equilibration, the microparticles

were washed with the respective assay buffers till the enzyme activity in the

washings dropped to zero. The microparticles were then equilibrated with 15 ml

of 1M maltose at 4 °C for 4 h. The alginate microparticles were then

magnetically separated and the eluate was dialyzed extensively against the

respective assay buffers (24 h at 4°C). The eluate was then checked for enzyme

activity.

3. Results

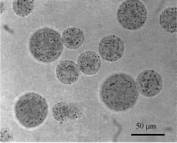

Microemulsion procedure with the organic solvent

partially miscible with water (1-pentanol) as the organic phase made it

possible to prepare spherical magnetic alginate microparticles having the

diameters in the range 25-60 (xm. The diameter of the prepared microparticles

varied slightly with the time of vortexing the emulsion. The magnetic phase was

homogeneously distributed throughout the particle volume (see Fig. 1). The

character of the organic phase (1-pentanol) enabled simple washing of the

prepared microparticles with calcium chloride solution which is a very cheap

and safe procedure. The magnetic alginate microparticles are easily

dispersible in water based solutions. The alginate magnetic microparticles also

bind bacterial and porcine pancreatic a-amylase activity just like the bigger

magnetic alginate particles (Teotiaand Gupta, 2001). The main advantage of

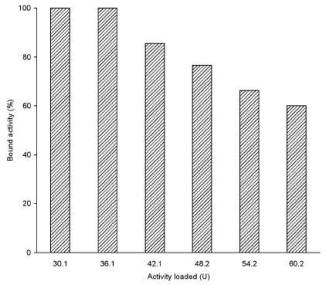

using smaller-sized particles is expected to be higher binding capacity. In

earlier work with alginate macroparticles, the binding capacity of 4.7 U

ml"1 (settled volume of magnetic particles) had been reported

with a commercial preparation of B. amyloliquefaciens a-amylase (BAN 240 L).

The alginate microparticles showed the binding capacity ca. seven times higher,

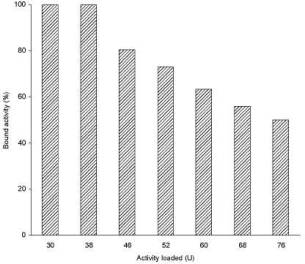

i.e. 36 U ml-1 (Fig. 2). Similar high capacity for porcine

pancreatic a-amylase (38Uml-1) was also observed (Fig. 3).

Fig. 1.

Optical microscopy of magnetic alginate microparticles (magnification: 400 x).

Fig. 2. Binding capacity of bacterial a-amylase on

magnetic alginate microparticles. Binding capacity was measured by

equilibrating 1 ml of different concentrations of the enzyme (0.5-1 ml of the

original enzyme solution diluted up to a total volume of 1 ml) with 1 ml of the

settled magnetic alginate beads overnight at 25 °C.

Fig. 3. Binding capacity of porcine pancreatic

a-amylase on magnetic alginate microparticles. Binding capacity was measured by

equilibrating 1 ml of different concentrations of the enzyme (0.4-1 ml of the

original enzyme solution diluted up to a total volume of 1 ml) with 1 ml of the

settled magnetic alginate beads overnight at 25 °C.

Table 1

Summary of the purification of a-amylase from BAN 240

L (a bacterial source) using magnetic alginate microparticles

|

Steps |

Activity (U) |

Protein (mg) |

Activity yield (%) |

Specific activity (Umg ') |

Purification factor |

|

Crude Wash Eluate (1 M maltose) |

580 1.5 511 |

8.3 6.8 0.8 |

100 0.3 88 |

70 0.2 638.7 |

1 - 9 |

The settled magnetic alginate microparticles (16 ml)

were equilibrated with 20 ml a-amylase at 25 °C for 1 h, washed with the assay

buffer and then equilibrated with 15 ml of 1 M maltose at 4°C for 4h. After

magnetic separation the eluate was dialyzed against the assay buffer (24 h at

4°C) and checked for enzyme activity.

Table 2

Summary of the purification of a-amylase from porcine

pancreatic extract using magnetic alginate microparticles

|

Steps |

Activity (U) |

Protein (mg) |

Activity yield (%) |

Specific activity (Umg ') |

Purification factor |

|

Crude Wash Eluate (1 M maltose) |

578.8 0.0 557.5 |

2.5 2.1 0.2 |

100 0 96 |

231.5 - 2787.5 |

1 - 12 |

The settled magnetic alginate microparticles (16ml)

were equilibrated with 20ml a-amylase at 25 °C for 1h, washed with the assay

buffer and then equilibrated with 15 ml of 1 M maltose at 4°C for 4h. After

magnetic separation the eluate was dialyzed against the assay buffer (24 h at

4°C) and checked for enzyme activity.

The magnetic microparticles could be used to purify

a-amylases from both these sources. It has been earlier shown that maltose

specifically elutes a-amylase from alginate beads (Sardar and Gupta, 1998).

Table 1 summarizes the purification process for BAN 240 L. The observed 88%

recovery of enzyme activity with 9-fold purification using alginate magnetic

microparticles is much better than 72% recovery with 3.6-fold purification

reported earlier using magnetic alginate macroparticles (Teotia and Gupta,

2001). Table 2 shows the purification of a-amylase from crude porcine

pancreatic acetone powder extract when 96% enzyme activity could be recovered with

12-fold purification. The specific activities indicate that the isolated

enzymes are of high purity (Mondal et al., 2003).

4. Discussion

The modified emulsion procedure using organic solvents

partially miscible with water as the oil phase (e.g. 1-pentanol) enables to

prepare magnetic alginate microparticles in a very simple way, without the need

of harsh organic solvents to remove the organic phase from the prepared beads.

This is a very important simplification of the existing approach. Magnetic

material is homogenously dispersed through the beads in sufficient amount

enabling efficient magnetic separation on a standard magnetic separator.

Prepared alginate microparticles were used for the

purification of selected a-amylases. The new magnetic alginate microparticles constitute much improved

affinity media for purification of a-amylases than larger particles. While only

the purification from mammalian and bacterial sources has been described here,

it is possible that just like the earlier macroparticles, these will also be

useful for isolation of a-amylases from other sources. Also, alginate has been shown to

constitute a macroaffinity ligand for other starch-degrading enzymes (Teotia

and Gupta, 2002), pectinase (Gupta et al., 1993), lipase (Sharma and Gupta,

2001) and phospholipase D (Sharma et al., 2000). Thus, the magnetic alginate

microparticles described here promise to be a multipurpose affinity media for

numerous enzymes of biochemical and biotechnological importance.

Acknowledgements

The research is a part of ILE Research Intention No.

AV0Z6087904. The experimental work was supported by the Ministry of Education

of the Czech Republic (Grant Project No. OC 523.80) and Grant Agency of the

Czech Academy of Sciences (Project No. S6087204). The partial supports provided

by Council for Scientific and Industrial Research (CSIR) (Extramural Division

and Technology Mission on Oilseeds, Pulses and Maize) and Department of Science

and Technology, both Government of India organizations, are gratefully acknowledged.

References

- Bradford, M.M.,

1976. A rapid and sensitive method for the quantitation of microgram

quantities of protein utilizing the principle of protein-dye binding.

Anal. Biochem. 72, 248-254.

- Brady, D., Nigam,

P., Marchant, R., McHale, L., McHale, A.P., 1996. Ethanol production at 45

°C by Kluyveromyces marxianus IMB3 immobilized in magnetically responsive

alginate matrices. Biotechnol. Lett. 18, 1213-1216.

- Burns, M.A.,

Kvesitadze, G.I., Graves, D.J., 1985. Dried calcium alginate magnetite

spheres—a new support for chromatographic separations and enzyme

immobilization. Biotechnol. Bioeng. 27, 137-145.

- Dekker, L.A.,

1977. Worthington Enzyme Manual. Worthington Biochemical Corp., Freehold,

NJ, pp. 173-176.

- Domingo, J.C.,

Mercadal, M., Petriz, J., De Madariaga, M.A., 2001. Preparation of

PEG-grafted immunomagnetoliposomes entrapping citrate stabilized

magnetite particles and their application in CD34+

cell sorting. J. Microencapsul. 18, 41— 54.

- Gombotz, W.R.,

Wee, S., 1998. Protein release

from alginate matrices. Adv. Drug Deliv. Rev. 31, 267-285.

- Gupta, M.N.,

Dong, G., Mattiasson, B., 1993.

Purification of endo-polygalacturonase by affinity precipitation using

alginate. Biotechnol. Appl. Biochem. 18, 321-327.

- Kiwada, H., Sato,

J., Yamada, S., Kato, Y., 1986. Feasibility of magnetic liposomes as a

targeting device for drugs. Chem. Pharm. Bull. 34.

- Mondal, K.,

Sharma, A., Gupta, M.N., 2003. Macroaffinity ligand facilitated three

phase partitioning (MLFTPP) of a-amylases using a modified alginate. Biotechnol. Prog. 19, 493-494.

- Roy, I., Sardar,

M., Gupta, M.N., 2000. Exploiting unusual affinity of usual

polysaccharides for separation of enzymes on fluidized beds. Enzyme

Microb. Technol. 27, 53-65.

- Safafik, I.,

Safafikov4 M., 1997. Overview of magnetic separations used in biochemical

and biotechnological applications.

In: Hafeli, U., Schutt, W., Teller J.,

Zborowski, M. (Eds.), Scientific and Clinical

Applications of Magnetic Carriers.

- Plenum Press, New

York, pp. 323-340. Safafikova, M., Safafik, I., 2001. The application of

magnetic techniques in biosciences. Magn. Electr. Sep. 10, 223-252.

Sardar, M., Gupta, M.N., 1998.

Alginate beads as an affinity material for alpha amylases. Bioseparation

7, 159-165.

- Sharma, S.,

Gupta, M.N., 2001. Alginate as a macroaffinity ligand and an additive for

enhanced activity and thermostability of lipases. Biotechnol. Appl.

Biochem. 33, 161-165.

- Sharma, S.,

Sharma, A., Gupta, M.N., 2000. One step purification of peanut

phospholipase D by precipitation with alginate. Bioseparation 9, 93-98.

- Smidsrad, O., Skjåk-Bræk,

G., 1990. Alginate as immobilization matrix for cells. Trends Biotechnol.

8, 71-78. Teotia, S., Gupta, M.N., 2001. Purification of alpha-amylases

using magnetic alginate beads. Appl. Biochem. Biotechnol. 90, 211-220.

- Teotia, S.,

Gupta, M.N., 2002.

Magnetite-alginate

beads for purification of

some starch degrading enzymes. Mol. Biotechnol. 20, 231-237.