|

|

sintesis of metallic

nanopowders by chemical vapor condensation (CVC) process |

|

|

|

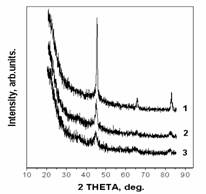

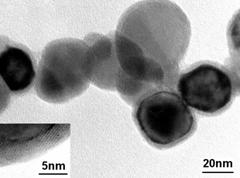

Fe

based nanoparticles encapsulated

by Fe3O4 oxide shells

|

Description We have studied the

production of metal-based nanoparticles by CVC process and capacity of this

method for getting powders with different chemical and granulometric

composition of particles. Generally, the full

scheme of CVC equipment can be described as follow. The carrier gas (inert or reactive) is feed through a heated

bubbling unit containing a liquid or solid precursor, which can be evaporated

without decomposition at comparatively low temperature. The flow of carrier

gas entraining a precursor vapour passed thought the heated tubular furnace

to a cooled chamber. This instrumented for the collecting of powder and

passivation process to the stabilization as-prepared particles. The most popular

precursors, which could be used in this method, are metal-organic compounds,

such as the carbonyls of metal, acetilacetonate compounds of metal, or other

compounds with the high vaporization tension. It could be for example nickel,

Ni (acac)2, and cooper, Cu (acac)2 acetilacetonates, iron Fe(CO)5,

tungsten W(CO)6 or cobalt Co2(CO)7 carbonils,

etc. Research chemical and

phase composition Fe-based nanoparticles sustain availability the even

surface shells consisted of magnetite Fe3O4, with

defined thickness and composition. The production particles shows range of goodness, specific physical and

mechanical characteristics. And could be use for working in air atmosphere. Advantages In the chemical routes, chemical

homogeneity is achieved and the particles size can be reduced in nanoscale

regime in wide diapason quite exactly. Process is very flexible, and

allows additions of independent evaporation units with different precursors.

It is very kindly for production of alloyed nanoparticles. The

important advantage of this method is a mass production of nanoparticles and

relatively high capacity of process. It is quite suitable for realization not

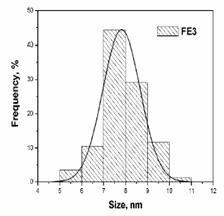

only for laboratory, but also for industrial application. We synthesized various kids of

metallic nanoparticles (Fe, Ni, Co, W) encapsulated by oxides, carbides or

pure carbon. Also alloyed and composite particles based on those components

have been produced. The average size of particles can be various from 6-100

nm and the shape can be different. The mechanism of forming nanoparticles and

the influence of experimental parameters on size distribution, structure and

chemical compound oxide- and carbon- coated nanoparticles were evaluated. |

|

|

|

|

|

|

|

|

|

|

|

|

|

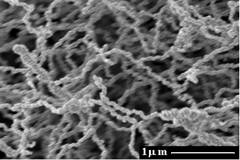

Fe particles encapsulated by carbon |

|

|

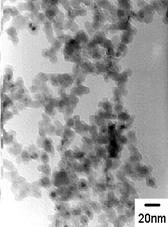

Fe-Co alloyed nanoparticles |

|

|

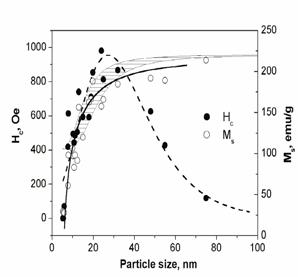

Size dependences of

saturation magnetization (Ms) and coercetivity (Hc)

of Fe nanoparticles |

Fields of application

ü

Especially, magnetic

nanoparticles can be used in magnetic fluids, magnetic inc, record media

devices, etc;

ü

Nanomedicine and

biotechnology;

ü

Permanent magnetization;

ü

Catalysts;

ü

Improving mechanical

properties of bulk materials and etc.

Metallurgical Faculty

Material Science Department

29 Politechnicheskaya st.

TOLOCHKO V. Oleg, Dr., Prof

Tel/fax.: +7(812)247-48-01 VASILYEVA

Ekaterina, researcher

katerina@ftim.spbstu.ru